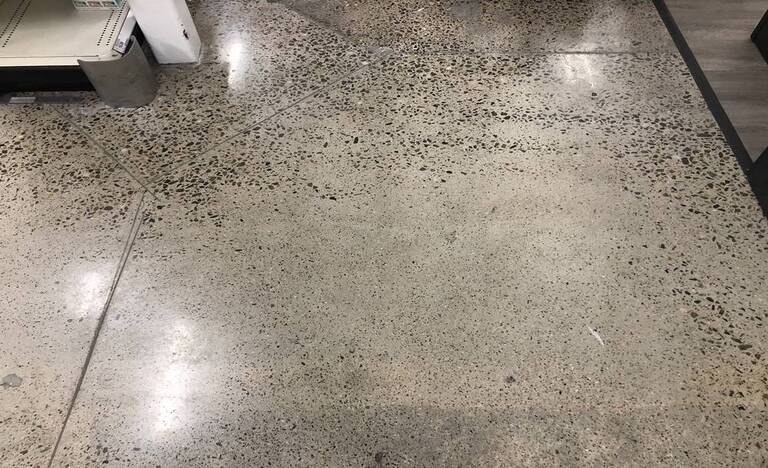

Concrete polishing has become a popular choice for flooring due to its durability, low maintenance, and aesthetic appeal. However, not all concrete surfaces are suitable for polishing.

Are you ready to redefine your space? Dive into the world of concrete composition and discover how the perfect blend of aggregates, cement, and water can create a floor that’s not just polished, but a true work of art.

Whether you’re envisioning a modern marvel or a timeless classic, understanding these elements is the first step toward a space that truly shines.

In the following article, we’ll examine the variables that influence how well concrete can be polished and examine which types of concrete are most suitable for achieving a polished finish.

Factors Affecting Concrete Polishability:

Concrete Mix Design: The concrete mix’s composition is a major factor in how polishable it is. Concrete with the right mix of aggregates, cement, and water, as well as the presence of additives like fly ash or silica fume, is more likely to be suitable for polishing.

Placement and Finishing Techniques: Proper consolidation and finishing of concrete are essential for achieving a smooth and uniform surface that is suitable for polishing. The timing of finishing operations also affects the final polishability of the concrete.

Concrete Age and Curing: The age of the concrete and the curing process it has undergone can impact its polishability. New concrete that has been properly cured is generally more suitable for polishing than older concrete.

Types of Concrete Suitable for Polishing:

New vs. Old Concrete: While new concrete is often more suitable for polishing due to its uniformity and lack of damage, older concrete can also be polished if it is in good condition and has been well-maintained.

Specialty Concretes: Specialty concretes, such as self-leveling concrete and decorative concrete overlays, can also be polished to achieve a smooth and attractive finish.

Concrete Unsuitable for Polishing:

Excessive Cracking or Damage: Concrete that has extensive cracking or damage may not be suitable for polishing, as the polishing process can further weaken the structure.

Highly Porous or Soft Concrete: Concrete that is highly porous or soft may not be able to achieve the desired polish, as these characteristics can affect the durability and finish of the polished surface.

Methods to Improve Concrete Polishability:

Surface Preparation Techniques: Proper surface preparation, including grinding and leveling the concrete, as well as using densifiers and sealers, can improve the polishability of concrete.

Concrete Repair and Restoration: Repairing cracks and voids in the concrete, as well as enhancing its surface hardness, can also improve its suitability for polishing.

Takeaway:

In conclusion, while not all concrete surfaces are suitable for polishing, many can be made suitable with the right techniques and treatments. It’s important to evaluate the condition of the concrete and consider factors such as mix design, placement, and curing before attempting to polish it. Polished concrete finishes can transform a space, providing a durable and attractive flooring option.

If your concrete project is only partially completed and you want the best Polished concrete finishes, get in touch with Old Stone Restoration & Installation Crop. They can help you achieve the perfect polished look for your space.