When it comes to selecting the finishing level for your concrete floors, the choices are nearly endless.

You may choose from low sheen to high polish.

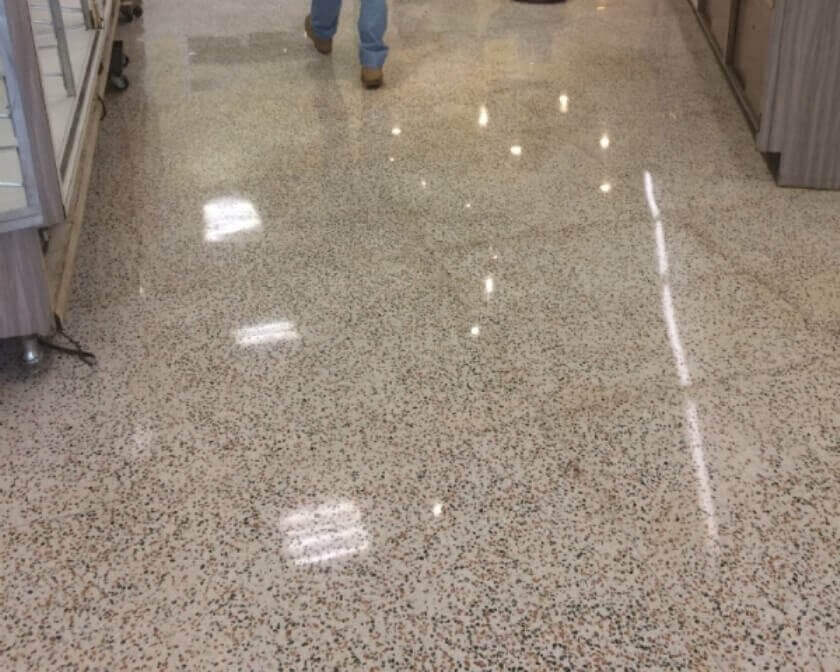

The aggregate look can range from minimally exposed (cream polished) to fully exposed (terrazzo look).

You have many colors and design options to choose from.

Selecting the finishing level that suits your needs will determine the amount of work that needs to go into the floor. A higher gloss level, more aggregate exposure, or adding colors will call for more stages, diamond tooling, and other products to achieve a higher-end finish.

Having a better understanding of what polished concrete is, what options are available, and how each process works will help you set your expectation level. You will then be able to wisely evaluate and choose your restoration contractor with higher confidence.

Concrete has various sizes of aggregate mixed in as part of its ingredients. Some pieces are large, and some are small. During the concrete-pouring process, as the concrete slab cures, the larger aggregates will settle toward the bottom, and the smaller ones will settle toward the upper surface. The contractor will then grind the floor to expose different grades of aggregate. As you grind deeper into the concrete slab, you will expose larger pieces of aggregate that are more uniform in size. There are four types of aggregate exposure level considered standard in the polished concrete industry. Let’s just categorize them as A, B, C, and D.

A) “Cream Finish”: The surface cutting depth is very slight and shows little or no aggregate exposure.

B) “Salt and Pepper Finish”: The surface cutting depth is around one-sixteenth of an inch and exposes finer to small aggregates. Depending on the floor’s flatness, this could also expose random batches of smaller aggregates, usually on the high spots of the floor.

C) “Medium Aggregate Exposure”: The surface cutting depth is around one-eighth of an inch and exposes medium-size aggregates. If large aggregates are exposed, they usually appear randomly on the high spots of the floor.

D) “Large Aggregate Exposure”: The surface cutting depth is around one-fourth of an inch and exposes large aggregates with more uniform consistency in aggregate size.

The other main aspect for polished concrete is the level of shine.

Selecting the gloss level on your concrete floors will also determine the amount of work that needs to go into the floor. A higher gloss requires more stages, diamond tooling, and other products to achieve a uniform, natural, deep gloss shine on your concrete floor.

The three most common gloss levels that property owners are choosing to suit their needs are named Satin Finish (also called “hone finish”), Semi-Polished Finish, and High-Polished Finish.

Polishing a concrete surface is no different than polishing other high-end, finer materials such as marble, granite, or terrazzo. They all need to be polished with diamond abrasives to achieve a natural mechanical polish across the material surface.

However, polishing each different material to achieve the desired gloss level will require a slight change of techniques, products and tooling for each material. For example, since the concrete is softer than most other natural stone type and it needs to be hardened with chemical called “Concrete Densifier/Hardener” so it can be polished with using diamond abrasives. To achieve a quality shine over the concrete surface concrete also requires much higher grinding pressure. To obtain the needed pressure, the concrete grinding machine needs to be much heavier—around 700 to 1,100 pounds, compared to the 180- to 600-pound floor machines used to grind and polish marble or terrazzo.

Other than the difference in machine weight, polishing concrete is the same as polishing other natural stone types. Obtaining natural shine over the material surface is all achieved by the use of diamond abrasives.

Depending on the condition of the material you are working with, selecting the diamond-abrasive grit number at the beginning and end of the grinding process will determine the natural gloss level that you will end up with. In other words, the higher the diamond grit number you use, the smoother and shinier the material will get.

General grit numbers on diamond abrasives for polished concrete start around #30 grit metal bond diamond for more aggressive grinding to expose aggregate and goes up to #3,000 grit resin bond diamond abrasives for achieving higher shine and reflective clarity.

To obtain a Satin Finish Look (Hone Finish) on concrete floors, the grinding process will stop at the #400 grit resin bond diamond abrasives. This grit number will produce a very low sheen finish on your material. When you look directly down at the floor, you will not see any gloss over the surface. If you look at the surface from a distance of around 30 feet or more, the floor will show a low sheen and may show slight reflection of the overhead lights.

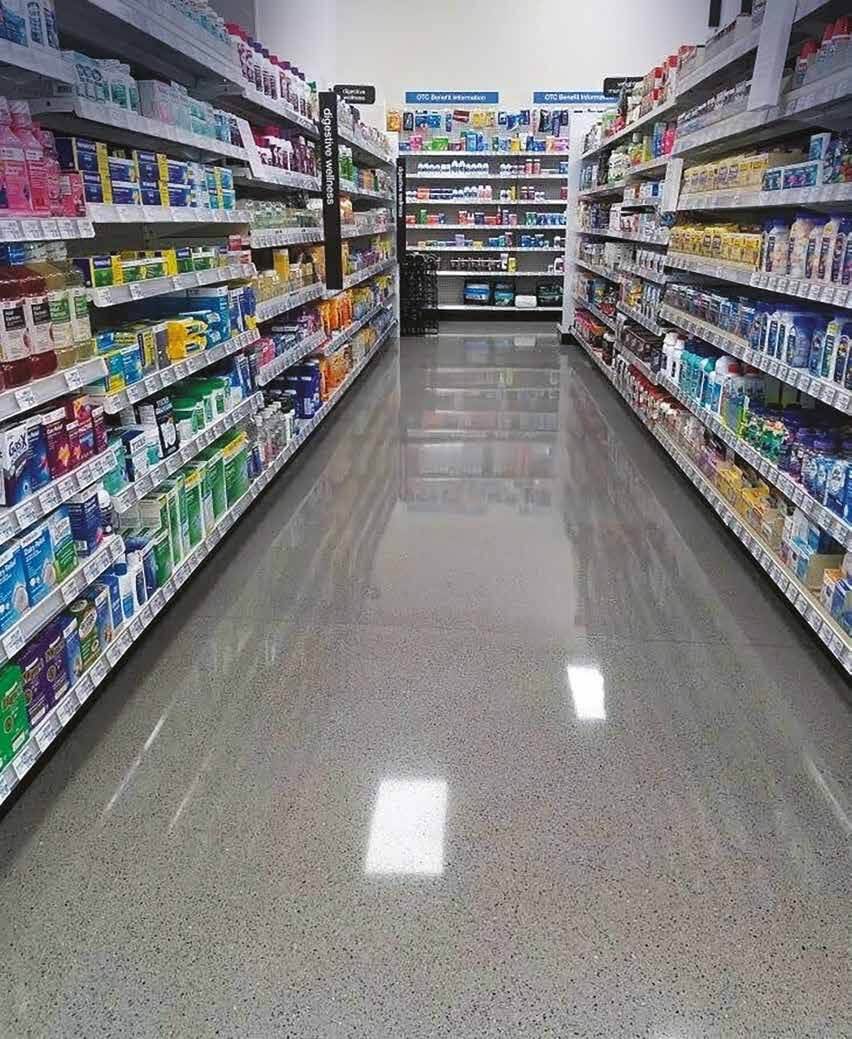

To obtain a Semi-Polished Finish on concrete floors, the grinding process will typically stop at #800 grit resin bond diamond abrasives. This grit number will produce a much higher sheen level than the satin finish. When you look directly down at the floor, you will see a glossier finish. If you look at the surface from a distance, the floor will clearly reflect the surroundings and the overhead lights.

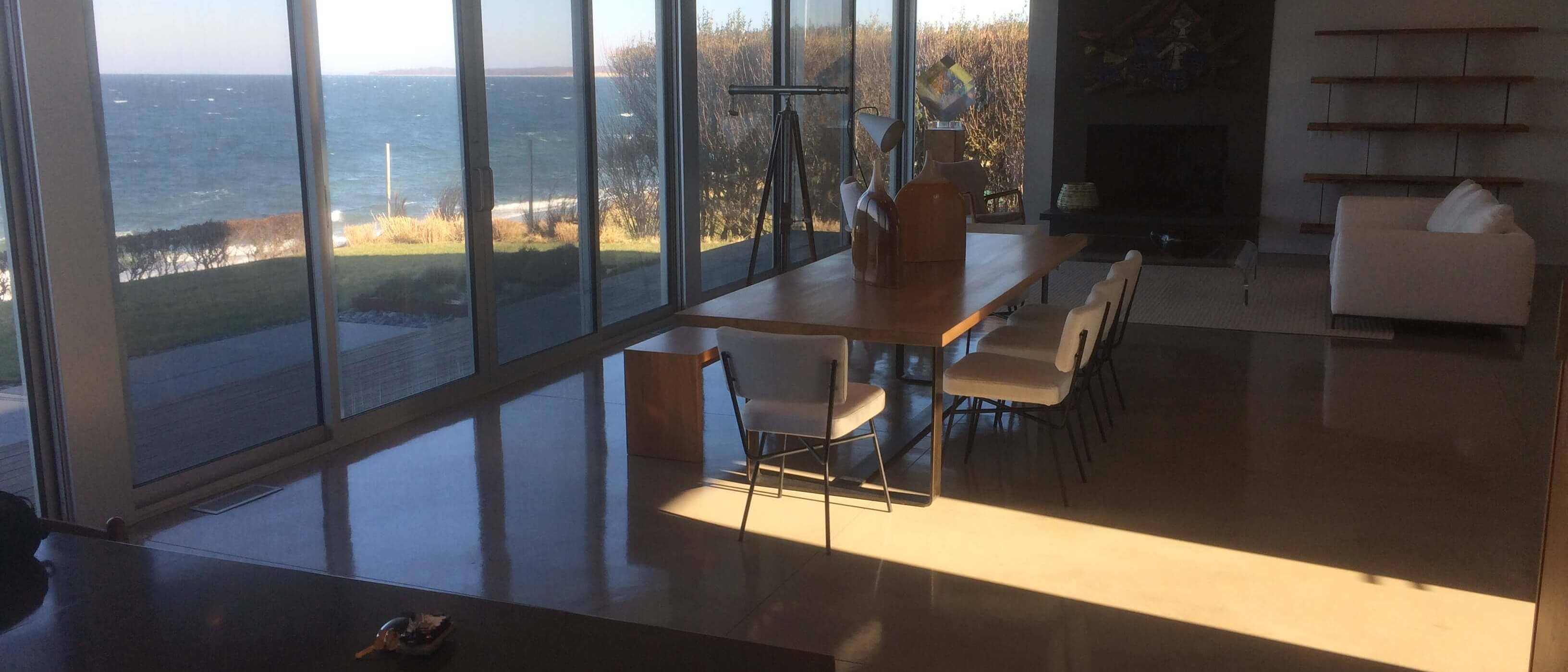

To obtain a High-Polished Finish on concrete floors, the grinding process will simply need to go up to #3,000 grit resin bond diamond abrasives. This grit number will produce a mirror-like reflection from a distance. The surrounding reflections and colors will be more defined, with clear reflections of overhead lights.

Concrete Quality

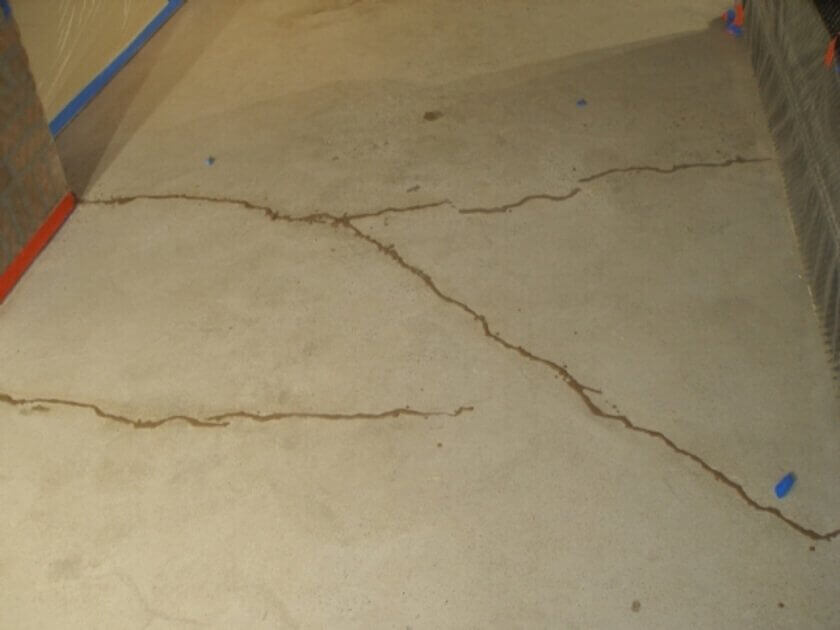

The quality of an existing concrete slab will determine the final appearance of that finished concrete floor.

Nearly every structurally sound concrete slab can be repaired and polished. The end-result appearance will vary from floor to floor.

However, floors that have been damaged and repaired extensively are not suitable for polishing. For those types of floors, the best option would be to install a self-leveling cementitious topical layer over the existing concrete slab floors.

These self-leveling cementitious toppings are suitable for residential, commercial, and industrial floors. These toppings can cover an existing floor with a three-eighths-inch to two-inch-thick layer. The new surface can be polished and colored like any other concrete floor. As a design option, you can also embed decorative aggregates, shells, and glass chips in your concrete during the pouring process. These will be exposed later with the polishing process.

To learn more or if you have questions on any other aspect of polished concrete floors, give us a call at (631) 821-5619

At Old Stone Restoration & Installation Corp., we are happy to answer any questions that you may have.

———————————————————–

We service the tri-state area and provide free evaluations for most locations on Long Island.

Whether it is a garage floor you would like to polish or any commercial or public building that requires polished concrete on their floors, we are at Old Stone Restoration & Installation Corp., have the knowledge, experience, and ability to assist you with installing and maintaining your next polished concrete project with confidence.

OUR PARTIAL LIST OF SERVICES FOR CONCRETE WORK

- Grinding and Polishing

- Sealer Applications

- Maintenance

- Self-Leveling Toppings

- Decorative Finishes

- Shot Blasting

- Epoxy and Other Type Coating Removal

- Crack and Joint Repairs