MENU

-

INSTALLATION

Epoxy Floor System

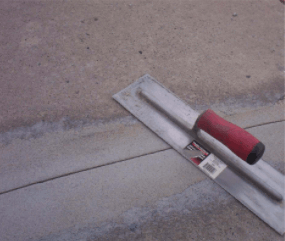

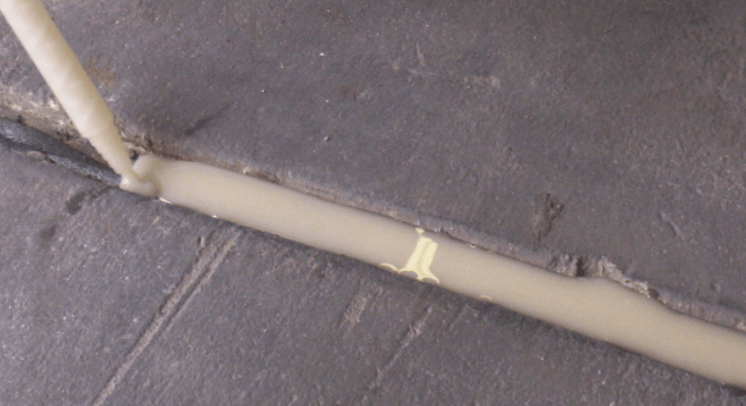

Chip Broadcast System Quartz Broadcast System Solid Color Epoxy System Metallic System Exterior System Epoxy/Urethane Mortars ESD/Anti Static System Concrete Repair SystemPolished Concrete

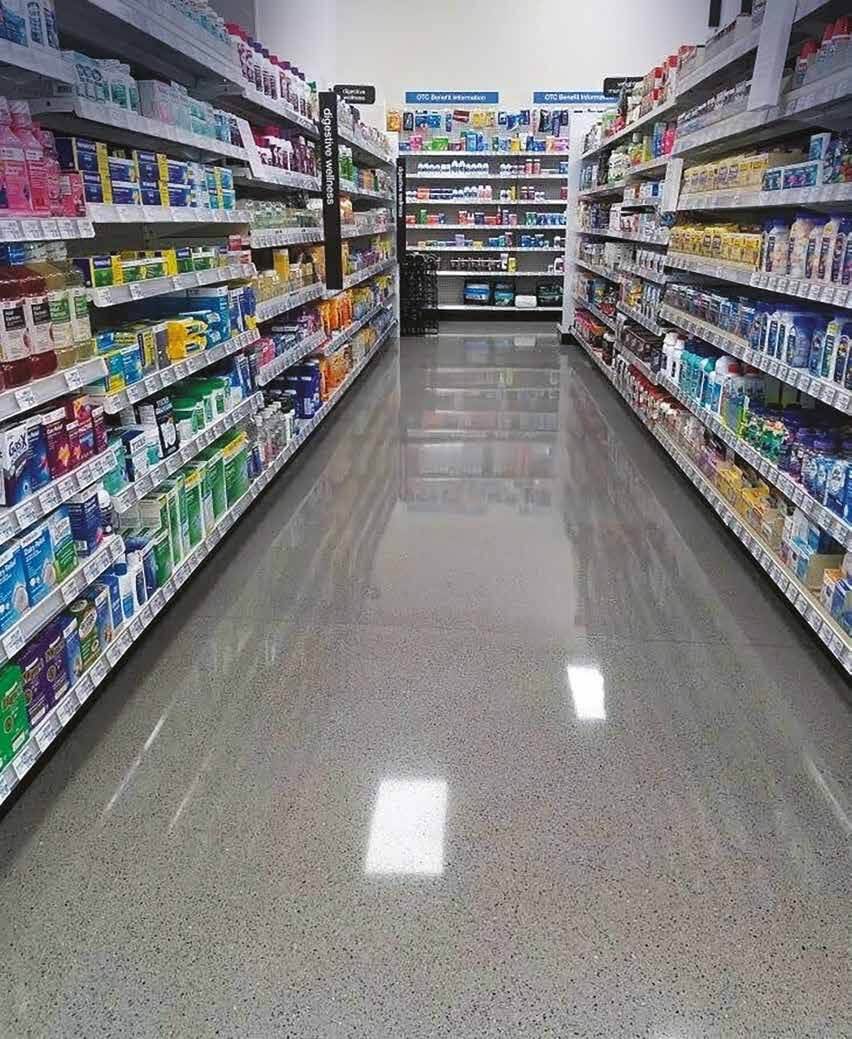

Polished Concrete Floors Self-Leveling Toppings Concrete Repair System Micro Topping Concrete Overlays Industrialist Epoxy Floor Contractors Concrete Waterproofing Concrete Sealers Travertine Cleaning ServicesMarble Tile Installation

Natural Stone & Tile Installation - RESTORATION

- RESIDENTIAL

- COMMERCIAL

- INDUSTRIAL

- BLOGS

- ABOUT US